Our next topic will be divided into two sub-topics, and they will touch a few important pressure gauge-related subjects that might help you decide which types of gauges are the perfect fit for your needs. The sub-topics are:

Gauge parameters (specifications)

Gauge types and application area

This article focuses on gauge parameters. Gauge types will be made available at a later time.

You might be familiar with the various parameters of a gauge, but if it is not the case, or you simply want a reminder on a few specific areas, this article is just for you. The areas that we will talk about are pressure ranges, accuracy, housing sizes, connection types, wetted parts, and liquid filling.

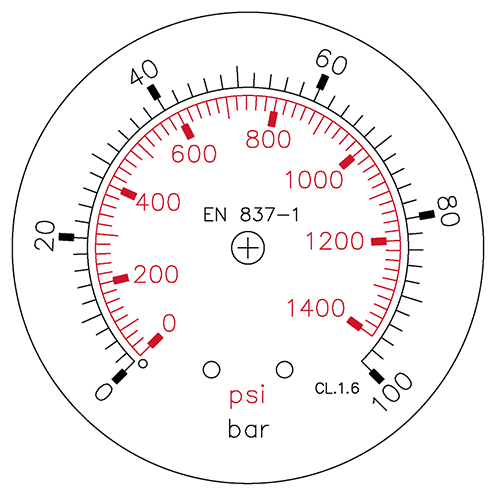

Pressure range

On our pressure gauges’ dial face, the unit of pressure is displayed in “bar”, “kPA”, and/or “psi” (pounds per square inch). Usually the best approach to select a gauge is to first learn the normal working pressure of your own system (for example 100 psi), then choose a gauge with a range around twice your system’s normal working pressure (in this case around 200 psi).

There are a few reasons why this, in most cases, is the best approach. First, pressure gauges are the most accurate in the middle-third section of their measuring range, and second, if the pointer is in the middle (pointing straight up), it is easier and faster to make sure everything is working as it should be, that is, the system is operating on its normal working pressure.

There are a few reasons why this, in most cases, is the best approach. First, pressure gauges are the most accurate in the middle-third section of their measuring range, and second, if the pointer is in the middle (pointing straight up), it is easier and faster to make sure everything is working as it should be, that is, the system is operating on its normal working pressure.

However, there are some other important factors you should be aware of. Selected pressure range should not be too low, as under extremely high pressure, the gauge might be damaged. A good practice is to choose one based on the type of pressure the gauge is subjected to. If the working pressure is on the same level most of the time, select a gauge that will most likely not exceed 3/4 of its dial range. But in case of alternating pressure or pulsation, it is better to select one that does not exceed 2/3 of its dial range.

Accuracy

When choosing a pressure gauge, determining accuracy need is key, as none of the other parameters influence more the price of a gauge than its accuracy. Thus based on your application, select a gauge that is accurate enough, but not overly accurate, because this can save you from a lot of unnecessary expenses. Gauge accuracy grades are specified by ASME B40.100 as follows: D, C, B, A, 1A, 2A, 3A, and 4A, where 4A is the most accurate and D is the least accurate.

| ASME Accuracy grade | First quarter of scale (%) | Middle half of scale (%) | Last quarter of scale (%) |

| 4A | 0.1 | 0.1 | 0.1 |

| 3A | 0.25 | 0.25 | 0.25 |

| 2A | 0.5 | 0.5 | 0.5 |

| 1A | 1 | 1 | 1 |

| A | 2 | 2 | 2 |

| B | 3 | 2 | 3 |

| C | 4 | 3 | 4 |

| D | 5 | 5 | 5 |

For example, when you hear “3-2-3”, it refers to a 3-2-3% accuracy “B grade” gauge. It means that in the middle half of the scale, the gauge has an accuracy of ±2%, but in the first and last quarter the pointer is ±3% off.

ASME grades 1A, 2A, 3A, and 4A have full scale accuracy, which means that the gauge shows the same accuracy in all four quarters. Therefore, if a pressure gauge is for your personal spray gun, probably you do not need the most accurate gauge available on the market, a “B grade” will do just fine. That said, an “A grade” is still affordable and still delivers a “2-1-2” accuracy.

Gauges with 1%, 0.5%, 0.25%, and 0.1% accuracy are for professional use, where noting 0.5 PSI pressure difference is imperative.

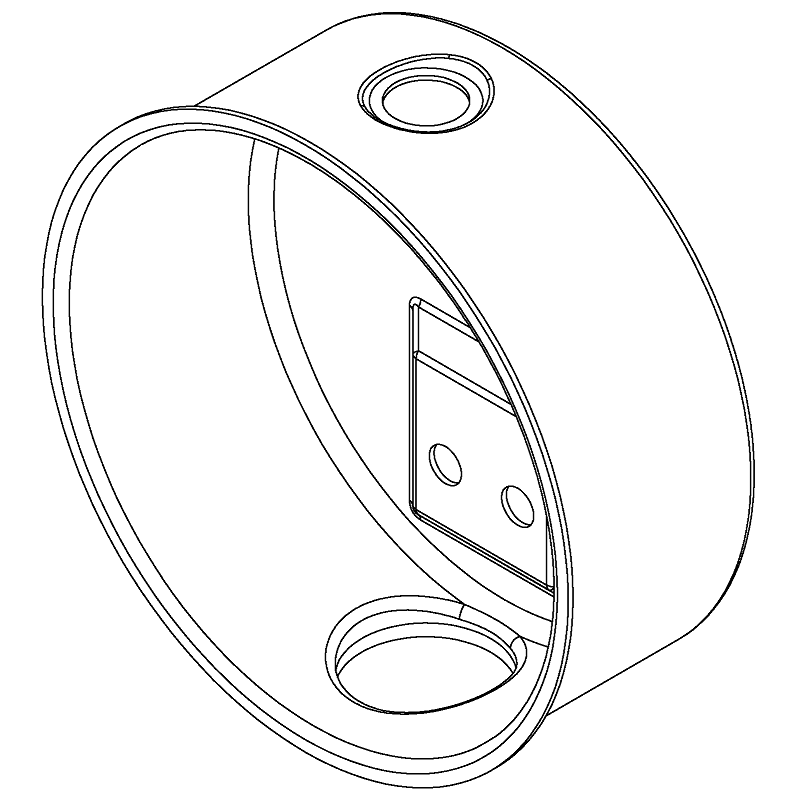

Gauge housing size

For our visitor’s convenience, on JIL Gauges’ website, every gauge size is indicated in inches and millimeters too. Sizes may vary from 30mm (1.5”) and up. If you are not sure about your requirements, the quickest way to select a size is to measure your old gauge’s size (not the front ring, but the back housing part), measure the place where you want to place the gauge, or to get in touch with us here. We can provide you with some additional tips.

For our visitor’s convenience, on JIL Gauges’ website, every gauge size is indicated in inches and millimeters too. Sizes may vary from 30mm (1.5”) and up. If you are not sure about your requirements, the quickest way to select a size is to measure your old gauge’s size (not the front ring, but the back housing part), measure the place where you want to place the gauge, or to get in touch with us here. We can provide you with some additional tips.

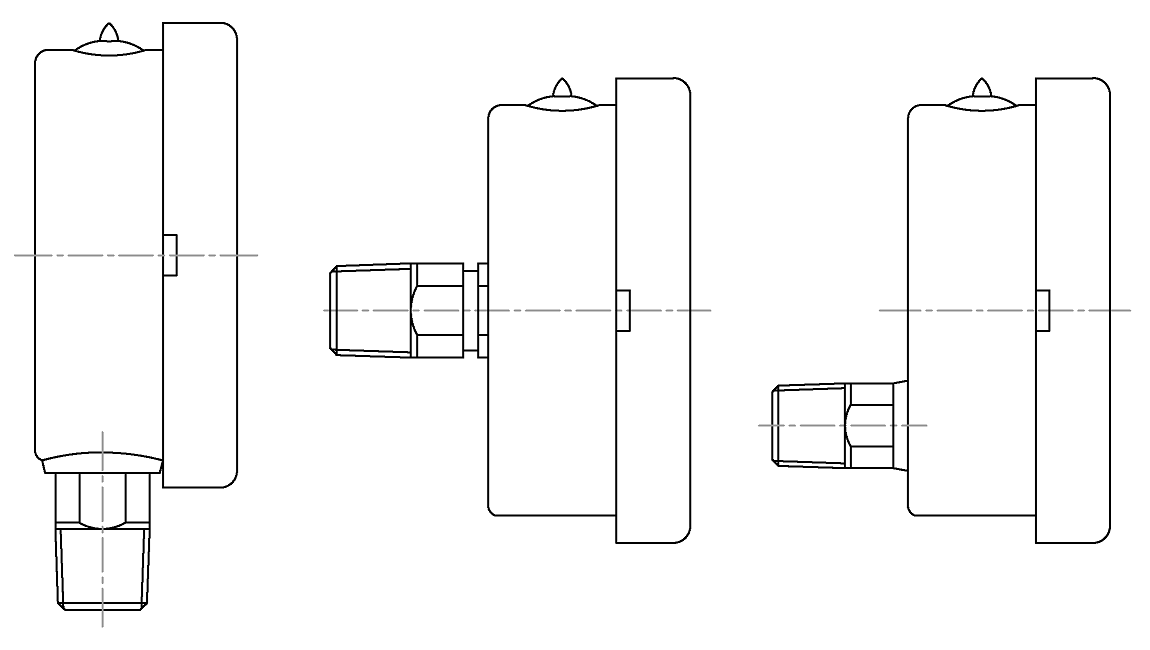

Mounting types

JIL Gauges usually provides three types of mounting options: BM (bottom), CBM (center back), and LBM (lower back). As their names imply, when we talk about BM - the connection is on the bottom of the gauge, CBM - the connection is in the middle of the back, and LBM - the connection is located on the back, but at a lower position. Nevertheless, whatever the mounting type is, because of their unique built, gauges should be mounted in an upright position.

JIL Gauges usually provides three types of mounting options: BM (bottom), CBM (center back), and LBM (lower back). As their names imply, when we talk about BM - the connection is on the bottom of the gauge, CBM - the connection is in the middle of the back, and LBM - the connection is located on the back, but at a lower position. Nevertheless, whatever the mounting type is, because of their unique built, gauges should be mounted in an upright position.

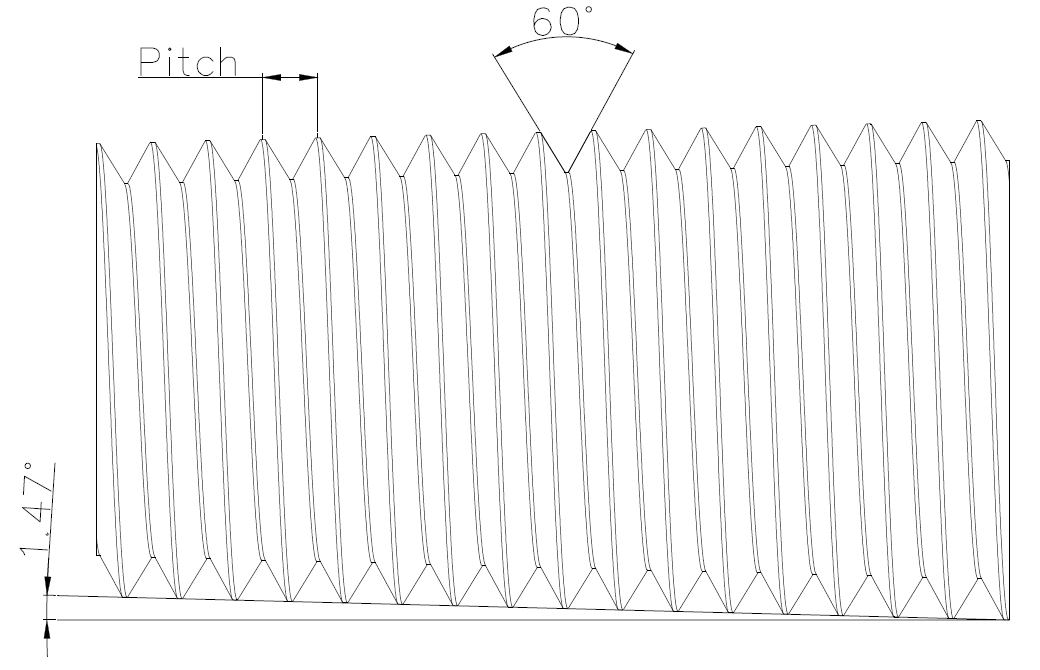

Thread types and sizes

Depending on the geographical location, environment and other factors, the industry uses different types of threads. The most common thread types are NPT (National Pipe Taper), NPS (National Pipe Straight), BSPT (British Standard Pipe Taper), and BSPP (British Standard Pipe Parallel).

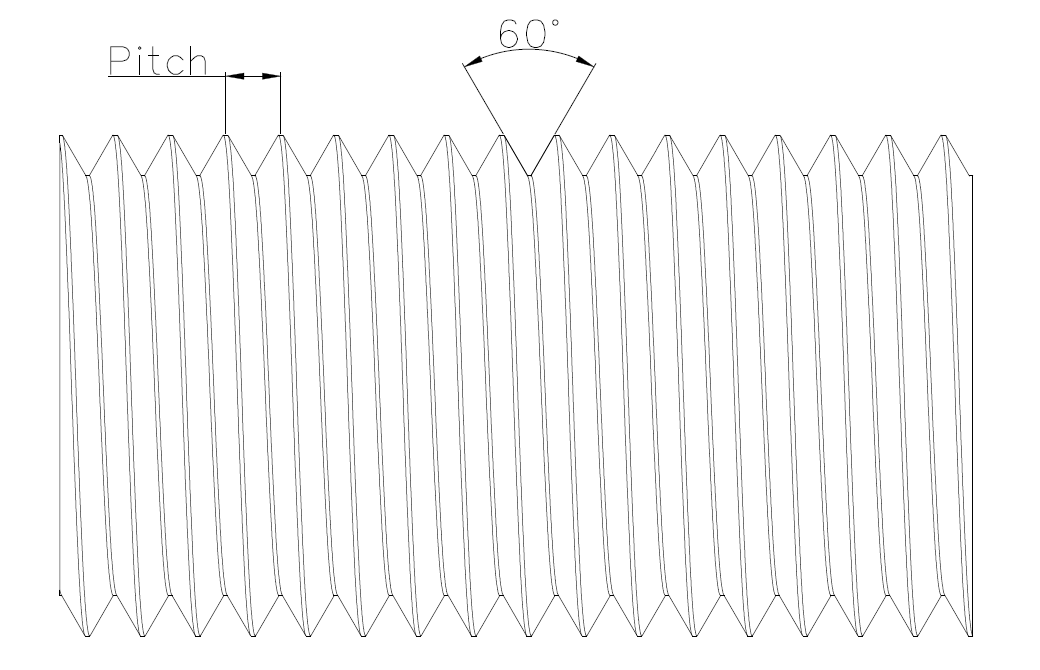

NPT and NPS are the most common in the USA and Canada and have a 60° included angle and Sellers thread form (flattened peaks and valleys). The main difference between the two is that the thread shape of NPT is tapered, and the thread shape of NPS is straight (parallel).

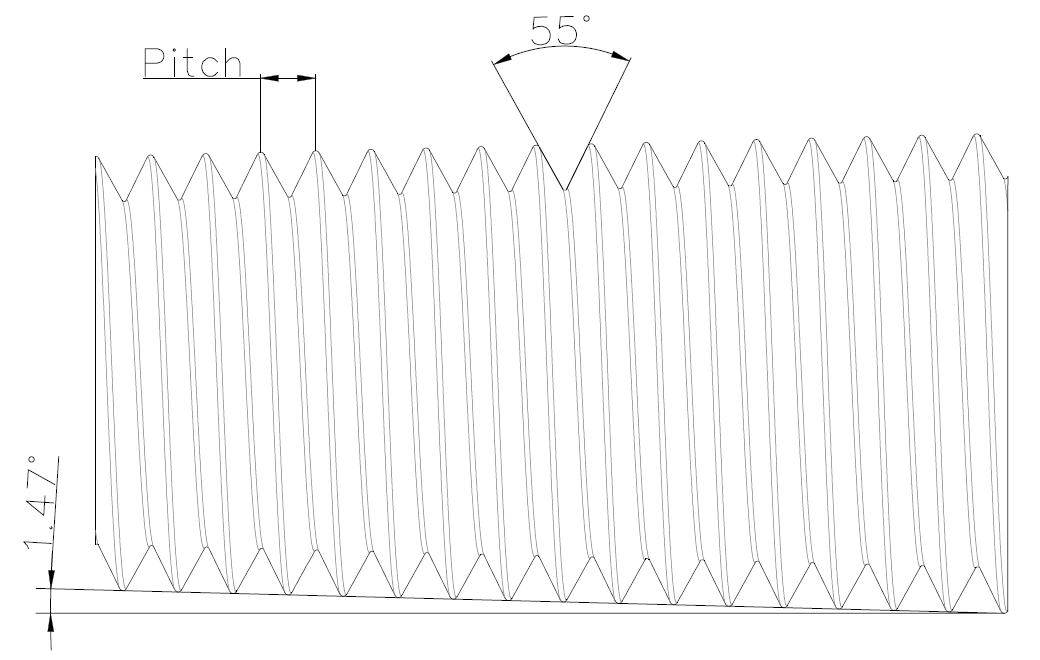

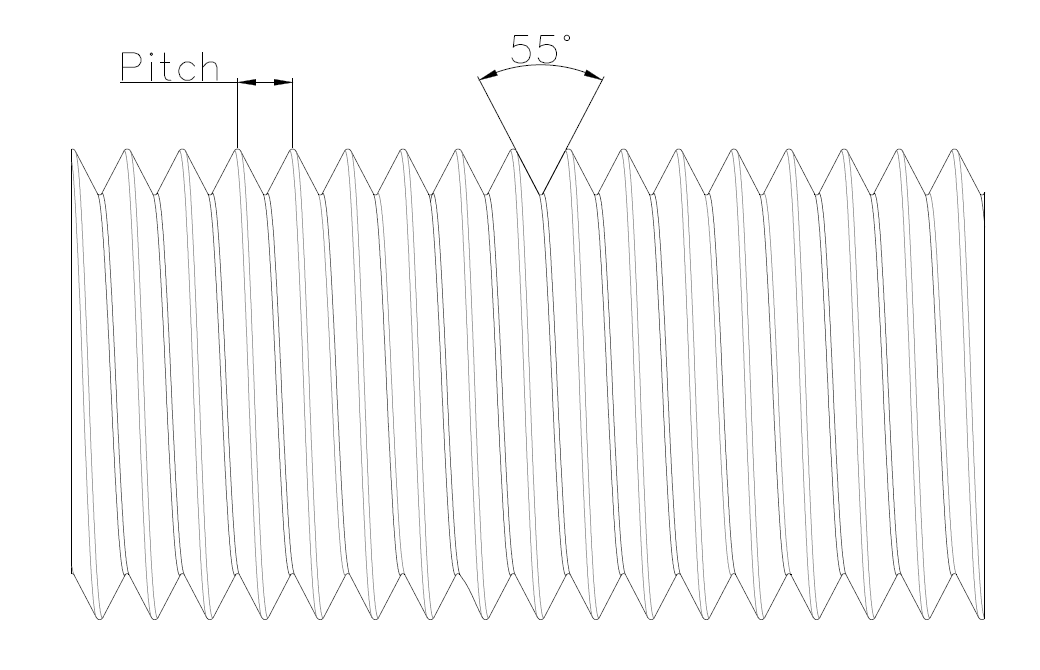

BSPT and BSPP, on the other hand, is wildly used anywhere else, all around the World, and have a 55° included angle, and Whitworth thread form (rounded peaks and valleys). And again, the main difference between the two is that the thread shape of BSPT is tapered, and the thread shape of BSPP is straight (parallel).

Thus NPT and BSP threads are not compatible with each other, and mating the two fittings is highly advised against! Always use the proper thread or an approved NPT-BSP adapter.

The most common thread sizes are 1/8”, 1/4”, 3/8”, and 1/2”. These numbers are trade sizes, and do not necessarily indicate actual diameters.

Wetted parts

Wetted parts are the parts that come in contact with the measured media (liquid, gas, and so on). These parts are most commonly made of brass, or stainless steel. Brass has the advantage of better price, and it is good for measuring non-corrosive media (air, water, gasoline, and so on), but on the other hand stainless steel is tougher, so it can withstand acid and other corrosive media better.

Liquid filling

Gauges can be liquid filled, liquid fillable, or dry. As their names suggest, liquid fillable gauges can be, but dry gauges cannot be filled with liquid by the end user. Liquid filled gauges are always filled with liquid by the manufacturer.

Filling a gauge with liquid (either silicone or glycerin) protects and lubricates the inner mechanisms, pointer, and dial face from frequent mechanical vibration, resonance, pulsation, or high temperature. Also steadies the pointer, thus making the dial face easier to read.